For a successful project management

Find out our 10 steps process for successful project management

that made our customers satisfied through 70 years of activity!

ELLE MARMI with its team of artisans, engineers and geologists, is able to follow all stages of project development from early assistance at a design stage for the choice of the most suitable materials, to executive drawings, stone processing, shipping of the material all over the world, and installation through specialized teams of supervisors and installers. Moreover, the customer can follow the whole process on the other side of the world.

ELLE MARMI 10 steps

1. Preliminary Study

Every request we receive is treated and studied in detail and with the utmost attention, be it a large project or a small order. The preliminary study begins immediately, to ensure the feasibility of the supply and the availability of the material, even in the case of special requests and processing.

In this way, your quotation will never refer to a standard price list, but will always take into account the actual availability of the material, the processing, and finishing required.

2. Material Consultancy

ELLE MARMI has no interest in using a specific material in its supplies; that’s why we are always open to deal with architects and customers, trying to meet their demands in the best possible way and within definite times.

Moreover, an experience of over seventy years allows us to be able to provide valid support and specialist advice, right from the early design stages and in the choice of the various materials that best suit the peculiarities of each project.

3. Site Inspection

Measuring the actual state of work is certainly one of the most delicate and important moments of the design process.

Upon request, we can carry out inspections and surveys, in Italy as well as abroad, also thanks to a network of collaborators with proven international experience.

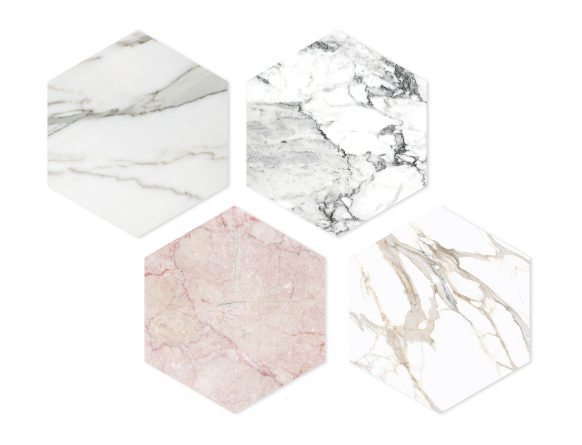

4. Procurement of the best materials

Our materials consultants choose the stones and marbles in person, directly in the quarries thus ensuring their origin and traceability. Each block and each individual slab is chosen to meet all the requirements of the project.

Furthermore, on request, we can send samples of the specified materials to the customer or the designer, for a direct and immediate evaluation of the product.

5. Executive Drawings and cutting lists

Our technical department checks the received executive drawings, and when necessary reworks them to make them suitable for their purpose: to recreate in stone what is written on paper.

On the basis of the drawings, the cutting lists are then elaborated, as a fundamental part of the manufacturing process. The cutting lists will guide our workers in the cutting and finishing phase.

The whole production is subject to high-quality criteria: the cutting lists are submitted to further customer approval, the slabs are numbered on the drawings and on the cutting lists, and the directions of the veins are defined with reference arrows to facilitate installation and make the most of the finished work.

6. Processing and quality control

The artisans of our workshop have been realizing your projects with passion and precision for seventy years. The material is examined during all stages of processing: the colors, structure, and direction of the veins are scrupulously checked.

Thanks to the state-of-the-art machinery in our laboratory, we are able to carry out any type of processing and cutting, with discs, cutter, or water jet, all strictly numerically controlled.

7. Dry Lay

In this phase, each piece is tested by means of a real dry laying, which allows us to simulate the future laying on-site and to photograph the pre-laid work.

The work is then subjected to final color and veins check.

8. Finishing by hand

The pieces are numbered and prepared for bespoke finishing: our artisans finish by hand practically every single piece produced, performing all those processes that cannot be made with the help of machinery.

This phase also allows us to carry out a further quality and measurement check.

9. Packaging and shipping

Finally, the packaging is designed and built to ensure the greatest possible safety during transport.

Depending on the size of the pieces, the means of transport, and the fragility of the goods, we pack in wooden crates or, when necessary, in multiple or reinforced packing crates.

The crates are numbered and labeled: the label shows the contents of the crate and the destination area on site.

A “packing list” is issued showing the qualities and sizes of the plates.

We equip each case with impact detectors, to report any unusual overturning or stress during transport.

Transport: on request, we can organize transport to any destination and reach all countries of the world.

10. Support

Our Support service can send specialized technicians to the construction site as installation supervisors, to check the installation and good execution phases, following our “Method of statement“.

ELLE MARMI also provides instructions for cleaning and maintenance for each type of marble or stone.

Rules to obtain a top quality product

We check every single step, beginning with the study of the most suitable materials based on the technical specifications of the products, to the choice of the blocks in the quarry, through the different processing stages to the final shipping.

We check the quality of the materials and products used in all stages of processing.

We constantly interact with the customer, his design team and the construction site, to guarantee full satisfaction in all aspects of the supply.

Detailed Custom Quotations

Get a quotation for your project in 24 hours!

We answer right away in Italian, English, French.

Contact us and we’ll start a preliminary study for your custom project.

Detailed Custom Quotation